E-waste is one of the largest and fastest growing waste problems we face today Ingram Micro is here to help …

What do millions of returned devices look like after they meet our techs? Good as new Our technology return centres …

See how much our business grew in APAC during 2020

Using our warehouse network, GovX orders are fulfilled from the east and west coasts, providing fast delivery and lower shipping costs to customers across the U.S.

Shipwire and Happy Returns Create Customer-First eCommerce Logistics

Expand Sales via Dropship and Marketplace Channels, and Improve Distribution and Fulfillment Capabilities

Learn how we adapted, pivoted our processes and maintained flexibility to meet the changing demands surrounding COVID-19 and supply chain impacts.

The secondary market for smartphones has been growing steadily for a decade. This white paper explores the dynamics of this market and examines how automation will change it.

Third party IT asset disposition in a post-pandemic world

Learn about how our U.S. Business performed during 2020.

Learn about how our Canadian Business performed during 2020.

Following careful planning and precise operational execution, we have led brands and retailers to ecommerce success this holiday season.

Back to the Roots, a popular DIY gardening kit company, partners with Ingram Micro and Logicbroker to realize B2B retail success.

Learn how to optimize your ecommerce technology. Download the full PDF for expert advice.

Factoring in COVID-19, it’s clear that this year’s shopping patterns are different than what we’ve seen in previous years.

Through the support of Ingram Micro, Vodafone’s Net Promoter Score increased overall customer satisfaction.

Camera accessory brand partners with Ingram Micro to ensure their brand experience exceeds customer expectations worldwide.

Learn why Canada represents a great opportunity to expand your eCommerce business.

All eyes on the global reverse logistics market Our returns centre in Europe processes 150K units a day.

A glimpse into Ingram Micro’s operations around the world for 2019.

Innovative sporting goods company, Storelli, grows through global ecommerce and retail channels

Our state-of-the-art facility and top talent come together to achieve incredible results.

Our logistics center in Daventry, UK offers a wide range of forward logistics and value added services.

Ingram Micro Commerce & Lifecycle Services share their thoughts on trends in the mobile phone insurance market and the changes that they are witnessing.

Learn more about holiday ecommerce trends through this visual infographic.

Go behind-the-scenes with Lang Moffat and learn about how Canada handles Peak.

Increasing distribution and brand exposure through a DirecTrak Sales Accelerator Program

Go behind-the-scenes with Mark Holland and ASOS’s operations

Businesses in Latin America are optimizing their supply chains and logistics operations.

Behind the scenes during the busiest time of year.

A useful infographic on reverse logistics and returns market trends and projections

Learn about setting up an eCommerce, logistics and fulfillment infrastructure in the Netherlands.

Liability, Insurance Coverage, and IT Asset Disposition

The vital role of Reverse Logistics and Repair in the Mobility Market

How to send products to a Shipwire-enabled Ingram Micro fulfillment center.

How we deliver exceptional peak season results.

Traditional brick and mortar retailer finds success in multi-channel sales.

Learn about eCommerce trends in Canada, shopper preferences and more.

Learn about end-of-life process with Ingram Micro ITAD.

Why ITAD data erasure standard has been replaced.

Germany’s role in logistics make it a logical hub for company expansion into the European Union.

Learn about European ecommerce fashion trends and projections by country.

Supply chain management is a complex operation. Save time and money by investing in a streamlined fulfillment and logistics protocol.

Noon Home, Inc. partnered with us to optimize omni-channel fulfillment through integration with the Shipwire Platform.

Ingram Micro implements a solution combining robust IT asset disposition with flexible redeployment services for U.S. offices.

Program elements to consider when developing, expanding, or consolidating an ITAD program, with focus on global coverage.

A nationwide financial institution with multiple data centers required a complex restructure plan.

An Inside Look at the Mobile Device Lifecycle.

Ingram Micro ITAD helps a national insurance company reduce IT asset disposition program logistics costs.

India’s unique challenges as the fifth largest e-waste producer in the world.

An infographic illustrating the evolution of the U.S. eCommerce market, from changing attitudes toward shipping times to top big-box industrial logistics marketings.

How a large healthcare organization accomplished a major corporate systems refresh in under 3 months.

LIFEAID partnered with Ingram Micro Services to support growing volumes and retailer success with the Shipwire Platform.

Vanity Planet, a leading beauty and personal care brand, partners with Ingram Micro Commerce & Lifecycle Services.

Learn about eCommerce & logistics markets in Canada.

Ingram Micro ITAD helped a pharmaceutical company meet strict ITAD security requirements & provided end-of-life solution.

How a major company captured all IT asset information across 270+ facilities nationwide in 90 days.

High online order volume required Ajax to partner with a best-in-class ecommerce fulfillment provider, Ingram Micro.

Ingram Micro ITAD helps implement a successful, centrally-managed global IT asset disposition solution.

Ingram Micro ITAD delivered a robust solution to keep field employees productive for a leading technology consulting and outsourcing company.

Drop ship information for suppliers and manufacturers.

Flexible and scalable technology to align with the rapidly evolving landscape of retail.

See how Ingram Micro Services is preparing for peak season.

Learn about why Australia is a strategically advantageous market for ecommerce sales.

A look inside an Ingram Micro facility and its capabilities.

Learn how standard receiving works at an Ingram Micro Services fulfillment center.

A quick look at the new Shipwire Platform Dashboard.

Ace & Tate partners with Ingram Micro Services to deliver a retail based shopping experience to their customers’ homes.

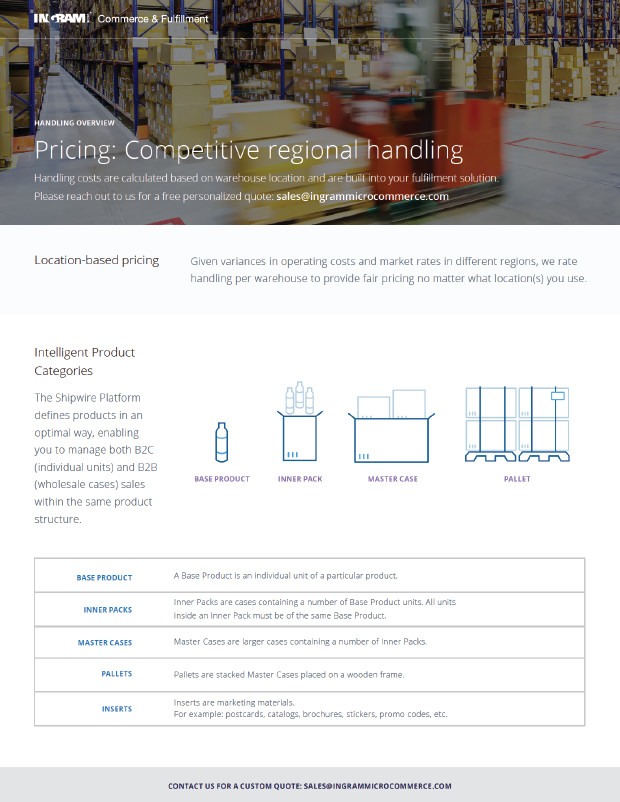

Learn how we calculate our competitive Storage pricing across our global fulfillment centers

Learn how we offer competitive order fulfillment.

De Bijenkorf partners with Ingram Micro Services to support a premium shopping experience.

GREATS Footwear went direct-to-consumer, preserving quality while maintaining low prices.

Ingram Micro Services provided order fulfillment for Seth Godin’s book, reaching over 30 countries worldwide.

Ingram Micro reduces manual intervention and increases speed to market for Little Unicorn.

GREATS Footwear continues to evolve their customer experience using the Shipwire Platform.

How The Grommet partnered with Ingram Micro to increase their sales by 450%.

The Shipwire Platform provides powerful Analytics to help you with your business.

How the most successful Indiegogo campaign in Australia partnered with Ingram Micro for success.

Setting up your product catalog in the Shipwire Platform.

Customize your delivery experience using the Shipwire Platform.

Learn how to develop a successful drop ship business.

A fully integrated EDI solution for Shipwire Platform customers.

Dastmalchi expanded sales channels and grew by 80 percent.